Lube-Free Chain for Food Production Environments

Since 1988, Tsubaki’s ‘Lambda’ lube-free chain design has been adopted by many different industries for a diverse range of applications. Designed with a special oil-impregnated bush, it is internally lubricated meaning it benefits from an extremely long operating life without requiring additional maintenance or messy external lubrication. To further benefit hygiene critical applications, the recently launched 6th generation chain will be supplied as standard with a food grade lubricant impregnated bush which also has the benefit of increasing the chain wear life by 30%.

There are obvious benefits to using lubrication-free roller chain in industries such as food processing and packaging, where product contamination cannot be tolerated. By eliminating external lubrication the chain is kept a lot cleaner, meaning that it is far easier to specify and install in areas with strict hygiene regulations in place.

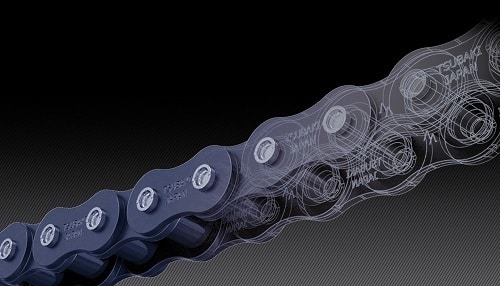

While the chain does need some form of lubrication to avoid premature wear, in the case of Lambda chain microscopic pores in the seamless sintered bush are vacuum filled and the lubricant is held in place where it’s needed most.

Four key features of Tsubaki Lambda chain: 1. Sintered oil impregnated bush, 2. Special coated pins, 3. Centre sink rivets, 4. Ring coin

While the majority of the lubricant is held in place, it is inevitable that a small amount will always migrate to the surface of the chain, meaning that it must be deemed suitable for use within the food industry. Food grade lubricant has always been available with Lambda chain, but now, for the first time, it is supplied as standard.

Brendan McConnell, Sales Director for Tsubaki Australia, comments: “Because of Lambda’s natural longevity and low maintenance costs, it’s popular across many industries and applications, not just hygiene critical ones. However, we recognise the clear advantages the chain has in such environments and wanted to make it as easy as possible for end users in these industries to specify our chain. This lubricant now meets all NSF-H1 requirements so can be used in situations where there is the possibility of incidental contact with food. Besides that the level of performance that our customers are used to with our standard Lambda has increased by 30%.”

Lubricants for use with or near foodstuff are graded into one of three designations, H1, H2 and H3. H1 lubricants may be used in applications where there is the possibility of incidental food contact. H2 lubricants are for locations where there is no possibility of contact with food. H3 lubricants are typically edible oils, and used when there is likely to be contact with food. For applications where there is significant contact with foodstuffs, Tsubaki usually recommends that stainless steel chains or Engineering Plastic Combination (PC) chains be used.

Many industries, including food and beverage production uses processes involving heating and/or cooling. Lambda chain can be used in temperatures from -10°C up to 150°C and a heat resistant Lambda (KF-Series) is available upon request that can be used in temperatures up to 230°C.

Tsubaki’s Lambda chain features many design innovations which makes it the most advanced lube free chain on the market. To learn more head to http://tsubaki.com.au or visit Tsubaki at Stand P47 on Level 1 at foodpro.

You may also like

-

Stay up to date with the latest news, industry insights and foodpro updates.

- Subscribe