For the food industry, hygiene has always been of the utmost importance. However, the pandemic has only reinforced this and the food safety monitoring processes manufacturers implement in their workplace.

If anything, 2020 has only proved that now is the time for businesses to re-evaluate their food safety practices and take further precautions when it comes to the food processing equipment being used.

HACCP & Food Safety Plans

The events of the pandemic have proved to be a reminder to all in the industry of how easy pathogens can transfer between humans, as well as from humans to other surfaces.

Food businesses need to respond to this concern by working hard to run through their food safety monitoring processes and applications of the HACCP Guidelines in their practices.

HACCP is the internationally recognised system that is used to identify and manage hazards; reducing risks of food contamination throughout the entirety of the production process.

Created as early as the 1960s, the HACCP was curated to control biological, chemical and physical hazards in the food production process.

HACCP Principles

Standing for Hazard Analysis Critical Control Point, the HACCP is comprised of seven principles:

- Conduct a hazard analysis

- Identify critical control points

- Establish critical limits

- Establish monitoring procedures

- Establish corrective actions

- Establish verification procedures

- Establish record-keeping procedures

It’s important to note that these principles apply to and are used at all points in the food production process, from growing and farming through to distribution and consumption.

The pandemic has acted as a big wake-up call for the food industry as a whole, but especially for the agricultural and horticultural sectors, places where viruses can spread easily, causing a loss of crops and short shelf-life products.

3 Ways to Ensure the Safety of your Food

There are a number of ways businesses can implement HACCP and a variety of food safety monitoring processes. Here are three ways that are recommended by industry leader Food Processing Equipment (FPE).

1. Eagle Food Inspection Machines

Advances in technology have enabled some HACCP control measures to become automated, helping to improve food safety practices for processors.

One company leading the way in product quality inspection equipment for the HACCP is Eagle PI.

Eagle Marketing Manager, Christy Draus says, “Smarter food safety is data-driven, …those in the food chain – including growers/farmers, manufacturers, retailers and foodservice operators are taking advantage of (or should take advantage of) technologies that allow for greater traceability and quicker responses to suspected illnesses or injuries.”

Supplied through FPE, all Eagle inspection machines come with the option of the HACCP compliance software, providing improved functionality, reporting and quality assurance traceability.

2. SYSPAL Sanitising Conveyors

As a requirement by the BRC Global Standard for Food Safety, businesses need to have physical segregation between low and high care areas.

To make meeting this requirement easier, SYSPAL provide their sanitising conveyors. The machines allow for the operator to pass utensils, raw ingredients (still in their packaging) and equipment through the segregation barrier between low and high care areas as safely as possible.

Not only do the conveyors allow for compliance by processing plants, but they also help eliminate risk of cross-contamination between production areas.

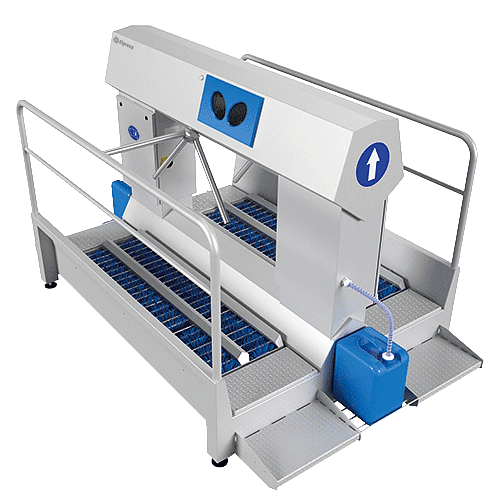

3. EIpress Personal Hygiene Systems

The EIpress machines are the industry-standard when we talk of industrial hygiene. The machines ensure that the transmission of pathogens in food processing plants through human contact is minimal.

The company also supply hygienic entrances, also known as hygiene locks, and washroom solutions, used by processors across the globe.

FPE are a supplier of Eagle, SYSPAL and EIpress machines, click here to find out more about their food safety monitoring processes and equipment.