Shaughan Syme first learned about the Japanese brand Rheon, which makes food-processing machines, while he was working for equipment supplier Ross Industries in the late 1980s.

“Almost immediately, I fell in love with the quality of the Rheon machines,” says Syme. “They just plugged in and worked straight out of the box.”

Syme was new to the food industry – he’d previously worked in the automotive sector – but he was an enthusiastic worker and rapidly rose through the ranks at Ross Industries. “I started off just taking care of one small product, and reasonably quickly grew to be a national manager for them, selling up to 26 types of food equipment,” he says.

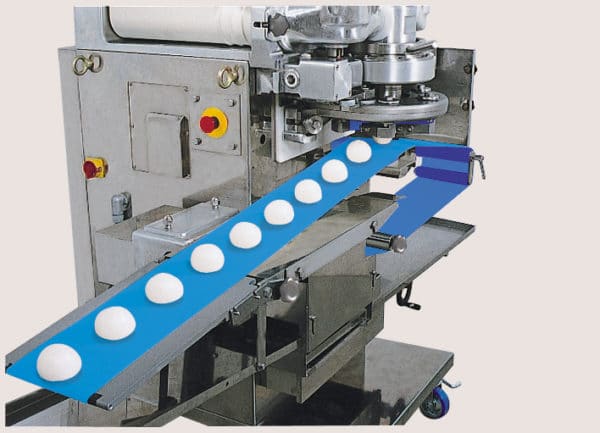

One of his responsibilities was to look after the Rheon account. “Rheon’s claim to fame is putting a filling inside a casing as a co-extruded product, not as an injected product afterwards, like you might put jam inside a donut,” Syme explains. “Rheon’s machines actually extrude the two materials together, one inside of the other.” Two high-profile examples are Ingham’s Duets and McCain’s Pizza Pockets.

By the mid 1990s, Syme’s job at Ross Industries was taking him all around the country. “In 1995, I had my second child, a daughter,” he says. “I realised that in my last two years with Ross Industries, I had been away 34 weeks of the year, and I’d missed a lot of my first-born growing up. I didn’t want to have to leave my daughter all the time, the same as I had with my son.” So, Syme gave his notice. He planned to join his wife’s successful software training business, but within weeks of leaving Ross Industries, he received a phone call from Rheon. “They approached me and said, ‘Look, your old boss doesn’t want to retrain anyone. We know that you did all the Rheon selling at Ross Industries. Would you like to have the agency [contract]?’ To which I said yes.” A new equipment-supply company, Symetec, was born.

For the first few years, Rheon – which also manufactures sheet line equipment for bread and pastries – was Syme’s only client, which gave him an opportunity to connect deeply with the Japanese brand. “Rheon are pedantic with their designs, manufacturing and presentation; I can truly say I’ve never had a machine from Rheon that hasn’t worked properly straight out of the box and continued to work like a finely made Swiss watch,” he says.

“There have indeed been other co-extrusion machines introduced to the market in recent years,” he continues, “but the areas where Rheon still shine are the extraordinarily wide range of product materials it can handle out of the one model, and the Rheon build quality.”

As Symetec grew, Syme began to represent other equipment manufacturers, such as British company Deighton. But Rheon remained integral to the business. In the years since, Rheon’s food equipment has become some of the most used in Australia.

Syme reckons Rheon’s remarkable dedication to its customers has played a big role in his own success. “Rheon’s customer care is exceptional,” he says. “They have technicians that travel from Japan for regular visits to the bigger sheet-line users in Australia, and while here we have the opportunity to use them for customer visits to service machines or to look at particular problems a customer may be encountering with maintenance.”

And, like Syme did at Ross Industries, all sales managers at Rheon start at the bottom and work their way up. “Any Rheon person who visits us, from the director down, is able to take off their suit coat, don a white lab coat and go out on the floor to fix a problem, or make a service adjustment, or assist our customer to make their product work a little better,” says Syme. “It’s extraordinary.”